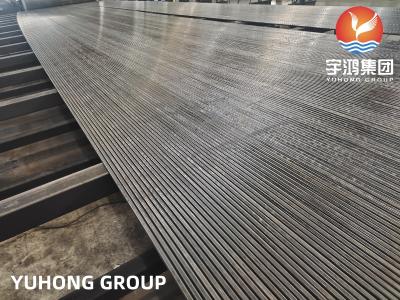

ASTM

A213

/

SA213

T11

T22

T23

T5,

T9,

T91

T92,

Boil

tube,

100%

Eddy

Current

Test

&

UT

Alloy

steel

tubes

is

a

kind

of

steel

alloyed

tube

with

other

elements

in

amounts

of

between

1

and

50%

by

weight

to

improve

its

mechanical

properties.Alloying

elements

are

added

to

achieve

certain

properties

in

the

material.

As

a

guideline,

alloying

elements

are

added

in

lower

percentages

(less

than

5%)

to

increase

strength

or

harden

ability

or

in

larger

percentages

(over

5%)

to

achieve

special

properties,

such

as

corrosion

resistance

or

extreme

temperature

stability.

Main

Materials:

ASTM

213(Seamless

Ferritic

and

Austenitic

Alloy-Steel

Boiler,

Superheater,

and

Heat-Exchanger

Tubes)

ASTM

A213

T5,

T9,

T11,

T22,

T23,

T91,

T92

ASTM

A335

(Seamless

Ferritic

Alloy-Steel

Pipe

for

High-Temperature

Service)

ASTM

A335

P5,

P9,

P11,

P22,

P91,

P92

ASTM

A/ASME

SA

213

specification

pipes

are

available

in

grades

including

T5,

T9,

T11,

T22,

T23,

T91,

T92.

ASTM

A/ASME

SA335

Grade

P5,

P9,

P11,

P22,

P91,

P92.

Alloy

steel

tubes

are

generally

available

in

stock

with

OD

sizes

in

all

standard

sizes

and

thicknesses.On

demand,

we

can

offer

our

customers

with

high

quality

alloy

steel

pipes

and

tubes

with

black

painting,

anti-corrosion

oil

and

galvanised

finish.

|

Trade

Name

|

Grade

|

UNS

#

|

Heater

Tubes

|

|

1

1/4

Chrome

|

T11

|

K11597

|

A213

/

SA213

|

|

2

1/4

Chrome

|

T22

|

K21590

|

A213

/

SA213

|

|

5

Chrome

|

T5

|

K41545

|

A213

/

SA213

|

|

9

Chrome

|

T9

|

K90941

|

A213

/

SA213

|

|

T91

|

T91

|

K90901

|

A213

/

SA213

|

|

T92

|

T92

|

K92460

|

A213

/

SA213

|

|

Trade

Name

|

Grade

|

UNS

#

|

Pipe

|

Forged

/

Bored

Pipe*

|

|

1

1/4

Chrome

|

P11

|

K11597

|

A335

/

SA335

|

A369

/

SA369

|

|

2

1/4

Chrome

|

P22

|

K21590

|

A335

/

SA335

|

A369

/

SA369

|

|

5

Chrome

|

P5

|

K41545

|

A335

/

SA335

|

A369

/

SA369

|

|

9

Chrome

|

P9

|

S50400

|

A335

/

SA335

|

A369

/

SA369

|

|

P91

|

P91

|

K91560

|

A335

/

SA335

|

A369

/

SA369

|

|

P92

|

P92

|

K92460

|

A335

/

SA335

|

A369

/

SA369

|

Chemical

composition(%):

|

Grade

|

C

|

Mn

|

P≤

|

S≤

|

Si

|

Cr

|

Mo

|

|

P11

|

0.05-0.15

|

0.30-0.60

|

0.025

|

0.025

|

0.50-1.00

|

1.00-1.50

|

0.44-0.65

|

|

P22

|

0.05-0.16

|

0.30-0.60

|

0.025

|

0.025

|

≤0.50

|

1.90-2.60

|

0.87-1.13

|

|

P5

|

≤0.15

|

0.30-0.60

|

0.025

|

0.025

|

≤0.50

|

4.00-6.00

|

0.45-0.65

|

|

P9

|

≤0.15

|

0.30-0.60

|

0.025

|

0.025

|

0.25-1.00

|

8.00-10.00

|

0.90-1.10

|

|

P91

|

0.08-0.12

|

0.30-0.60

|

0.020/0.010

|

0.020/0.010

|

0.02-0.50

|

8.00-9.50

|

0.85-1.05

|

|

P92

|

0.07-0.13

|

0.30-0.60

|

0.020/0.010

|

0.020/0.010

|

≤0.50

|

8.50-9.50

|

0.30-0.60

|

Mechanical

properties:

|

Grade

|

Tensile

strength

|

Yield

strength

|

Elongation

|

|

P11,

P22,

P5,

P9

|

≥415

|

≥205

|

≥30/20

|

|

P91

|

≥585

|

≥415

|

≥20

|

|

P92

|

≥620

|

≥440

|

≥20

|

Type:Seamless

Form:Round

Pipes/Tubes,

Square

Pipes/Tubes,

Coiled

Tubes,Pan

Cake

Coils,

Hydraulic

Tubes

Length:Single

Random,

Double

Random

&

Required

Length

End:Plain

End,

Beveled

End,

Treaded

End

Protection:Plastic

Caps

Outside

Coating:Black

Painting,

Anti-Corrosion

Oil,

Galvanized

Finish,

Finish

as

per

customer

Requirements

Inspection,

Test

Reports:Mill

Test

Certificates,

EN

10204

3.1,

Chemical

Reports,

Mechanical

Reports,

PMI

Test

Reports,

Visual

Inspection

Reports,

Third

Party

Inspection

Reports,

NABL

Approved

Lab

Reports,

Destructive

Test

Report,

Non

Destructive

Test

Reports.

![]()