| Price | USD1000~10000 |

| MOQ | 1set |

| Delivery Time | 7-10 work days |

| Brand | YUSHUNLI |

| Place of Origin | Dongguan,China |

| Certification | CE |

| Model Number | PCB separator machine |

| Packaging Details | plywooden case |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 200Sets/Month |

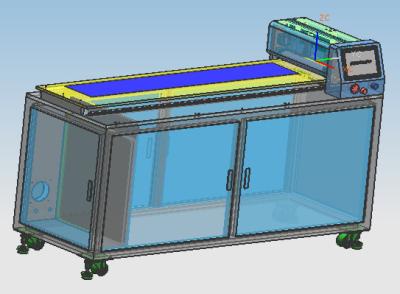

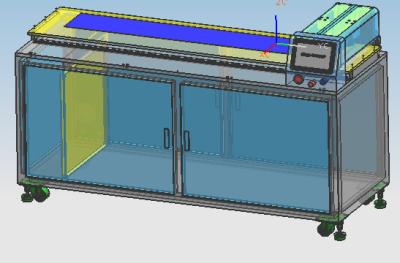

| Place of Origin | Dongguan,China | Size | 1850*560*1450mm |

| Packaging Details | plywooden case | Model Number | PCB separator machine |

| Supply Ability | 200Sets/Month | Certification | CE |

| Board length | 300~1200 mm(can sustom made) | Weight | 200kg |

| Brand Name | YUSHUNLI | Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Working pressure | 0.6~0.8Mpa | Price | USD1000~10000 |

| Delivery Time | 7-10 work days | Minimum Order Quantity | 1set |

| Plate accuracy | 0.1mm | Operation mode | Automatic operation |

Automatic Operation 200KG LED 1850*560*1450mm Light Strip Depaneling Machine

| Dimensions:L1300*W900*H1900 | |||

| Cutting width : Max 300mm Power: 500W | |||

| Blade size: 356*38*6mm (Straight knife) | |||

| Working pressure 0.5~0.8Mpa Weight: 450kg | |||

| Program programming, automatic feeding and cutting machine. |

Features:

|

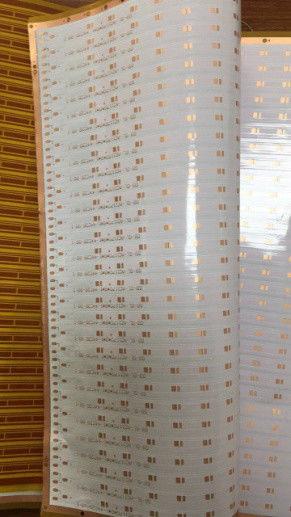

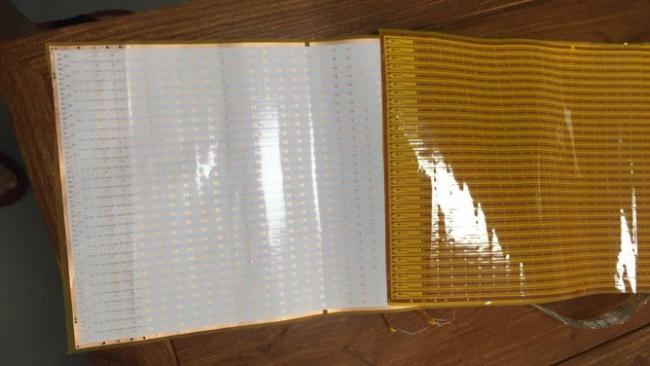

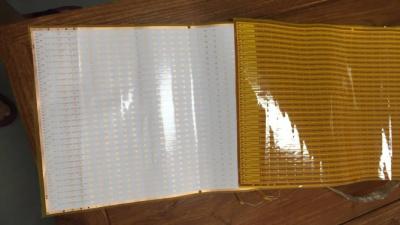

Cutting boards Fiberglass board, FR4 board, aluminu m substrate, copper substrate, etc. |

|||

| Positioning According to the V cut line positioning, the screen displays the feed data. | |||

| 1. For the pcb cutting equipment developed by COB light source board, the microcomputer is used to control the automatic feeding board. | |||

| 2. The efficiency is 5~6 times faster than the traditional board machine. | |||

| 3. When the cutting is performed, the micro stress of the components is about 200, to avoid tin cracking and prevent damage of precision parts. | |||

| 4, gas hybrid design, double straight knife depaneling, especially suitable for dividing precision PCB board | |||

| 5. Scythe work, suitable for various thickness MCPCB, the cutting stroke is below 2mm. | |||

| 6, anti-dwelling structure design, there is no operational safety concerns. |