| Price | Negotiable |

| MOQ | 1 |

| Delivery Time | Negotiable |

| Brand | Perfect Laser |

| Place of Origin | Hubei |

| Certification | CE |

| Model Number | PE-3012 |

| Packaging Details | Sea-Worthy Packing or Air-Worthy Packing |

| Payment Terms | L/C, D/A |

| Supply Ability | 5000 Unit per Year |

| Place of Origin | Hubei | Workbench structure | Thickened sheet metal structure, profile welding |

| Packaging Details | Sea-Worthy Packing or Air-Worthy Packing | control | Desktop computer or laptop supports win7 win10 XP system |

| Drive motor | High speed stepper motor (86 57) | Model Number | PE-3012 |

| Drawing software | CDR AotoCAD/CaxaCAD (planar software) | Supply Ability | 5000 Unit per Year |

| Certification | CE | Supported file formats | Standard G-code |

| Operating voltage | AC220V/50Hz | Brand Name | Perfect Laser |

| Payment Terms | L/C, D/A | Price | Negotiable |

| Cutting accuracy | The error is between 0.2-0.6MM (factors such as heating wire material, environment and foam dryness and humidity) | Minimum Order Quantity | 1 |

| Drive | 860 542 Driver |

Automatic Vertical Table-type Hot Wire CNC 3D Foam Cutting Cutter Machine

Model: PE-3012

★ Machine Introduction

The foam cutting machine features an integrated intelligent control system that simplifies operation and enhances cutting accuracy. Its innovative multi-axis linkage technology supports multi-dimensional cutting, including partial 3D modeling-free processing. The foam cutting machine is effectively used in manufacturing everyday products, crafts, and industrial components. In the future, there will be iterative upgrades towards fully automated high-precision direction.

★ Machine Features

1. Gantry Structure : The CNC foam cutting machine features an integrated sheet metal-formed structure and a 20mm laminated tabletop, ensuring precise vertical and horizontal alignment.

2. Intelligent Operation: The machine’s system directly reads CDR/CAD drawings, with built-in 3D simulation and programming-free cutting.

3. High-precision Transmission: Combination of ball screw and linear guide, with an accuracy of ± 0.05mm and a lifespan of over 50,000 hours.

4. Safety System: Dual servo emergency stop and breakpoint resume functionality, with insulation protection rated at IP54.

5. Multi-dimensional Processing: The CNC foam cutting machine is equipped with a four-axis linked rotating disc, supports the processing of 2D to 4D shapes, and can optionally include a multi-wire cutting module.

★ Appliaction

The foam board cutting machine can be used in the following area :

1. Multidimensional Modeling Engineering: Exhibition Beauty, Urban IP Sculpture, Architectural Decoration (Relief Roman Columns)

2. Solutions for Irregular Fonts: Multidimensional Curved Characters, Spherical Gradient Characters, Slanted Luminous Characters

3. Precision Casting Matching: lost Foam Casting, Five Axis Curved Mold, Shock-absorbing Packaging Module

Technical Specification

| Product Name | Automatic Vertical Table-type Hot Wire CNC 3D Foam Cutting Cutter Machine |

| Common Sizes |

2212 (width 1.35m / length 2.2m / height 1.25m) 3012 (width 1.35m / length 3m / height 1.25m) 3030 (width 4m / length 3m / height 1.25m) 2525 (width 2.5m / length 2.5m / height 1.25m) |

|

Working stroke 772(cutting size) |

The above dimensions are all processable dimensions, not equipment dimensions |

| Cutting accuracy | The error is between 0.2-0.6MM (factors such as heating wire material, environment and foam dryness and humidity) |

| Supported file formats | Standard G-code |

| Workbench structure | Thickened sheet metal structure, profile welding |

| Operating voltage | AC220V/50Hz |

| Transmission mode | X-axis: double high-precision circular rails (high-precision screw rack transmission) |

| Y-axis: double high-precision circular rails (high-precision ball screw transmission) | |

| Drawing software | CDR AotoCAD/CaxaCAD (planar software) |

| Operating software | CNC USB (supports cutting of 2D planes, 3D models, vertebrae, etc.) |

| Drive | 860 542 Driver |

| Drive motor | High speed stepper motor (86 57) |

| Work surface | 20MM thickness and density multi-layer plywood, high flatness and high temperature resistance |

| control | Desktop computer or laptop supports win7 win10 XP system |

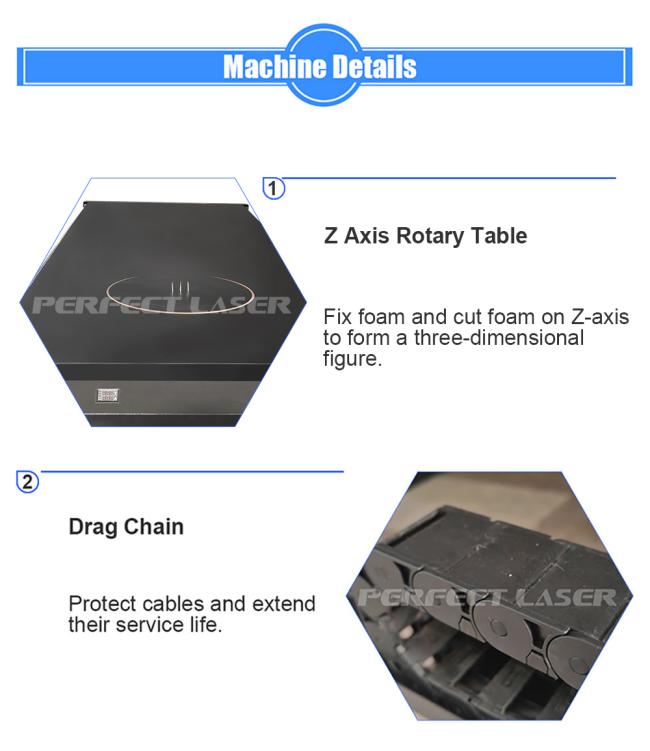

| Cables | Highly flexible and wear-resistant shielded cable |

| Operating software | The software can automatically program and three-dimensional stereo can also automatically plan the path, which is simple and convenient |

| Optional power | Single-filament machine to multi-filament machine |

| Add horizontal axis |

★ Packaging & Delivery

1.

Prompt

deliver

at

the

very

day.

2.

Sophisticated

and

professional

logistic

agent.

3.

Well-trained

and

disciplined

packing

team.

4.

After-sale

service:.

Any

questions

or

problems

after

receiving

the

product,

please

feel

free

to

contact

us.

Problems

would

be

solved

for

you

immediately.

★ Competitive Advantages

1.

We

offer

high

quality

products

at

competitive

price

in

quick

delivery.

2.

100%

custom

pass

guaranteed.

3.

Good

after-sale

service.

4.

Flexible

and

Untraceable

payment

terms.

5.

Our

products

have

been

exported

to

Germany,

Norway,

Poland,

Finland,

Spain,

UK,

France,

Russia,

USA,

Brazil,

Mexico,

Australia,

Japan,

Korea,

Thailand,

Indonesia,

Uruguay

and

many

other

countries.