| Price | To be quoted |

| MOQ | 1 |

| Delivery Time | 7 working days |

| Brand | kingpo |

| Place of Origin | china |

| Certification | iso9001 ce |

| Model Number | ISO 16750-4-figure4 |

| Packaging Details | safety carton pack or plywood box |

| Payment Terms | T/T |

| Supply Ability | 200 pcs per month |

| Place of Origin | china | number of cycles | 100 |

| Packaging Details | safety carton pack or plywood box | water temperature | 0 °C to +4 °C |

| Model Number | ISO 16750-4-figure4 | Supply Ability | 200 pcs per month |

| Certification | iso9001 ce | Brand Name | kingpo |

| Payment Terms | T/T | test fluid | de-ionized water |

| Price | To be quoted | Delivery Time | 7 working days |

| Minimum Order Quantity | 1 | holding time,th, at Tmax | 1 h or until DUT temperature stabilization is reached |

| transition duration | <20 s | water flow | between 3 l and 4 l per 3 s (splash duration) |

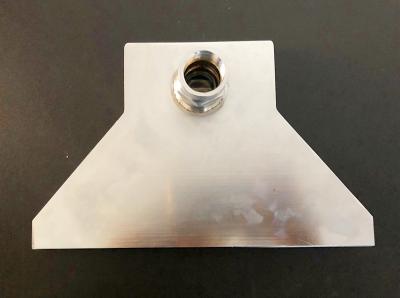

ISO 16750-4 Figure 4 Stainless Steel Test Set - Up For Splash Water Test Jet

Purpose:

This test simulates the exposure of the component to splash water as it occurs when driving through puddles.

The test is intended to verify the function of the component when exposed to abrupt cooling by means of water.

Test:

Operating mode of DUT:

If the component is not operated with operating load in driving mode:

II.a during the entire test

If the component is operated with operating load in driving mode:

Intermitting II.a and II.c during working condition driving

Test procedure:

Heating of DUT to test temperature.

This is followed by the cyclic splashing of the DUT as per Figure 35.

The DUT shall be splashed over its entire width.

Technical parameters :

| Model | KP-IW16750A |

| Studio size | 1300X900X900mm(D×W×H)mm |

| Test samples max | 700X700X500mm |

| maximum load bearing | 150kg |

| temperature range | RT+10℃~200℃ |

| Temperature fluctuation: | ±2℃ |

| Temperature deviation: | ±2℃ |

| Test hole | Φ100mm |

| Power | AC380V 50Hz 25kw |

| Control system | PLC Electric Control |

| Operation interface | 7 inch color touch screen operation |

| Test model | Splash water test |

| Test cycle | Default 100 cycles, 0-9999 can be preset |

| Splash duration | 3s |

| Splash water temperature | 0-4°C |

| Water flow | 3-4L/3s |

| Distance of nozzle to DUT | 300-350mm |

| Orientation of the splash water | The sample is placed on the turntable according to the actual use, according to the actual situation to choose the positioning (single-direction splash) or rotation mode (multi-directional spray) |

| DUT heating | Heating system |

Introduction to structural design

1. The outer casing of the equipment is made of 2mm high-quality galvanized steel plate CNC machine tool, and the surface of the outer casing is sprayed, which is more smooth and beautiful.

2, the liner is SUS316 high-quality stainless steel mirror panel; in order to facilitate the recycling of the test medium and the cleaning after the Zui, the bottom of the equipment studio is designed as a funnel;

3, insulation material: high-density fiberglass cotton to ensure insulation performance, maintain indoor balance and stable temperature;

4. The door is provided with a transparent window for observing the change of the indoor sample, and the observation window is made of multi-layer hollow tempered glass;

5. The mixing system adopts long-axis fan motor and high-low temperature resistant stainless steel multi-wing impeller to achieve vertical convection vertical diffusion cycle, so that the temperature and humidity in the laboratory are uniform and stable;

6. Double-layer high-temperature resistant high-strength sealing strip is used between the door and the cabinet to ensure the sealing of the test area. The inner door material of the door is made of stainless steel, and the door handle is made without reaction, which makes the operation easier;

7. Test hole (left side of the machine) can be used for external test power cable or signal cable (100mm aperture);

8. The refrigeration system of the equipment is installed at the bottom, and the compressor is imported from Taikang brand in France to ensure the cooling effect and reliability.

9. The bottom of the machine is equipped with a high-quality fixed PU movable wheel, which can easily move the machine to the designated position, and fix the caster after the Zui;

10. The control part of the equipment is designed on the right side of the equipment. It is distributed with temperature controller and control switch. It is easy to operate, simple and easy to maintain.

Equipment use conditions

1. the ambient temperature: 5 ° C ~ +32 ° C;

2. Ambient humidity: ≤85%;

3. power requirements: AC380 (±10%) V / 50HZ three-phase five-wire system;

4.pre-installed capacity: about 3KW

Spray Nozzle-Kingpo

PLC Controller-SIEMENS

Touch screen- SIEMENS

5.4.2 Splash water test

5.4.2.1

Test

method

Heat

the

DUT

in

a

hot

air

oven

at

Tmax for

the

specified

holding

time,th.

Then

splash

the

DUT

with

ice

water

for

3

s.

If

the

DUT

is

splashed

in

the

vehicle

from

only

one

direction,

splash

it

from

this

direction

only

while

it

is

in

an

as-installed

position.

If

the

equipment

is

splashed

from

various

directions

in

the

vehicle,

then

these

directions

shall

be

taken

into

account.

In

this

case,

use

a

new

DUT

for

each

splash

direction.

The

width

of

the

splash

directed

at

the

DUT

shall

always

be

greater

than

the

width

of

the

DUT.

If

the

DUTs

to

be

splashed

prove

too

big

for

one

jet,

arrange

several

jets

in

a

row

to

produce

a

line

of

splash

impact

on

the

DUT.

See

Figures

4

to

6.

Test

parameters

include:

⎯number

of

cycles:

100;

⎯holding

time,th,

at

Tmax:

1

h

or

until

DUT

temperature

stabilization

is

reached;

⎯transition

duration:<20

s

(for

manual

transition

of

DUT

between

temperature

storage

and

splashing);

⎯test

fluid:

de-ionized

water;

⎯water

temperature:

0

°C

to

+4

°C;

⎯water

flow:

between

3

l

and

4

l

per

3

s

(splash

duration);

⎯distance

between

jet

and

DUT

surface:

(325±25)

mm

(water

shall

be

applied

over

the

complete

width

of

the

DUT);

⎯operating

modes:

see

Figure

5;

⎯orientation

of

the

DUT:

as

in

the

vehicle.

Packaging