| Price | Negotiable |

| MOQ | 1 PC |

| Delivery Time | Negotiable |

| Brand | Hongsen Intelligent |

| Place of Origin | People's Republic of China |

| Model Number | HS-FK |

| Payment Terms | L/C, T/T |

| Valve hole size | 50 mm | Place of Origin | People's Republic of China |

| Use | Carcoal Powder Activated Carbon Graphite | Automation level | Full automatic |

| Model Number | HS-FK | Brand Name | Hongsen Intelligent |

| Payment Terms | L/C, T/T | Price | Negotiable |

| Minimum Order Quantity | 1 PC | Filling range | 10-50 kg |

| Drive | Pneumatic | Package | Valve bag |

| Packing accuracy | ±0.5~1% |

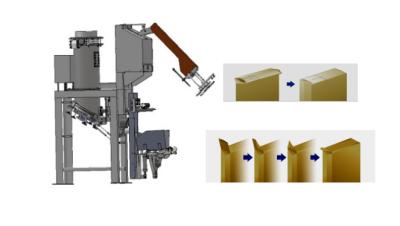

Carcoal Powder Activated Carbon Graphite Bagging Machine Automatic Valve Bag Filling

One full automatic pneumatic type valve bag filling machine comprises of:

1. PVPE (Pneumatic Valve Packing Equipment);

2. Manipulator (mechanical arm);

3. Bag magazine;

4. Conveyor.

The PVPE (Pneumatic Valve Packing Equipment) is an air flow bagger designed to fill dry solids, like granulated pellets, cement, adhesives, renders, powders, small aggregates and flaked products into valve bags. The PVPE works on the basis of air fluidisation of the product and differential pressure resulting in product flow into valve bags. This equipment can also be customized as per different customers’ special requirements. The PVPE Packer weighs the bag and contents as it is being filled. The filling speed relates to material ratio, fluidity, granularity, humidity, etc.

Bag Magazine (Empty bag depot):

It is big enough to keep 120 empty bags here and there is still place more bags. This bag magazine coordinates the automatic bag-fetching manipulator to realize fully automatic operation of bag taking. When the present batch of bags are used up, the next batch will be automatically replenished. The operator on site can put the bags into bag magazine while the machine is running. So there is no need to stop the production for supplement which will ensure continuous packing.

Materials to Fill:

Including but not limited to dry powders, premixes or materials of diameter less than 7 mm

Typical materials: PVC powder, renders, cement, gypsum powder, dry mortar, fine sand, lime powder, tile adhesives, joint mixture, charcoal powder, graphite, grain, flour, chemical powders, perlite, and all kinds of powdery additives.

Main Data:

| Packing range | 10-50 kg |

| Packing accuracy | ±0.5~1% |

| Valve hole size | 50 mm, filling spout |

| Valve hole length | 90-165 mm |

| Bag length | 90-180 mm |

| Bag height | 300-900 mm |

| Air consumption | To be specified |

| Material feeding mode | Slow and quick two modes |

If you want to change bag size?

1.

for

changing

bag

length,

you

just

need

adjust

length

value

on

the

machine

controller

2.

for

changing

bag

width,

you

need

change

another

set

bag

former.

one

kind

bag

width

correspond

one

bag

former

mode.

If

you

want

to

change

bag

weight?

Generally,

one

set

machine

can

pack

bags

of

different

weight,

but

the

changed

weight

at

a

certain

weight

range.

If

out

of

this

range,

then

need

change

another

set

measuring

systerm

(such

as

volumetric

cup,

screw/auger

feeder,

piston

pump

and

liquid

pump),

of

course

except

multihead

electric

weigher.