| Price | Negotiable |

| MOQ | 1set |

| Delivery Time | 35days |

| Brand | CHBEST |

| Place of Origin | Hebei, China |

| Certification | CE/BV/SGS |

| Model Number | CHBEST-686 |

| Packaging Details | standard |

| Supply Ability | 15sets/month |

| Place of Origin | Hebei, China | Warranty | 2 year |

| Packaging Details | standard | Color | As you requires |

| Control System | PLC | Model Number | CHBEST-686 |

| Supply Ability | 15sets/month | Certification | CE/BV/SGS |

| Name | Roof Double Layer Galvanized Trapezoidal Shape Making Roll Forming Machine | Brand Name | CHBEST |

| Delivery Time | 35days | Working Speed | 8-12m/min |

| Minimum Order Quantity | 1set | Voltage | 380V/50VHZ/PHASE |

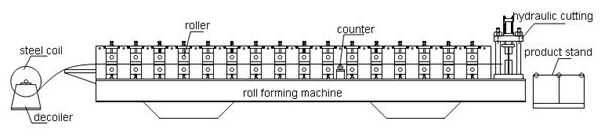

Roof Double Layer Galvanized Shape Making Roll Forming Machine

Company Profile

Cangzhou Best Machinery Manufacturing co., LTD is specialized in the manufacture of high-end equipment cold bending forming equipment manufacturer,has a professional engineer for technical guidance.Engineers engaged in cold bending mechanical equipment design for more than 20years,has a wealth of design concept.Can provide users with a special type of design and manufacture.At the same time to sell equipment for installation,guidance,production,commissioning one-stop service.

Machine Components

Decoiler-----------------------1set

Roll Forming Machine------1set

Cutting Device---------------1set

Hydraulic Pump--------------1set

Control System--------------1set

Output Table-----------------1set

Working Flow

Decoiler--Feeding--Roll Forming--Cutting--Output Table

Main Parameter

| Shaft Material | No.45 steel with treatment |

| Roller Station |

up 16 steps down 18 steps |

| Main Shaft Dimension | 70mm |

| Material Thickness | 0.3-0.8mm |

| Roller Material | No.45 steel with treatment |

| Working Speed | 8-12m/min |

| Material | PPGI/GI |

Decoiler

Capacity: 5000kg

Width: 1250mm

Type: Hydraulic Or Manual (Optional)

Inner Diameter: 450-550mm

Outter Diameter: 1500mm

Roll Forming Machine

Power: 3kw

Frame panel thickness: 14mm

Bottom Frame: 360H steel

Weight: 5t

Cutting Device

Type: Hydraulic

Driven; 1 inch chain

Power; 3kw

Cutting Blade: Cr12 steel

Hardness for Heat Treatment:HRC55 – 60°

Control System

Type:

PLC

Frequency

Control

System

with

touch

screen

PLC

Brand:Delta

Encoder

Brand:

Omron

Length Error: ±2mm

Language: English and Chinese

Hydraulic Pump

Power: 3kw

Oil Type: 46# hydraulic oil

Pump Brand: China Brand

Output Table

Length: 6m

It is simple and used to load finished product.

Our Service

Payment

type:

30%

T/T

prepaid

and

balance

should

be

paid

before

loading

Delivery

time:

30days

after

receving

advance

payment.

Guarantee

period:

18months

free

service/

pay

service

all

the

machine

life

Installation

and

training:

If

buyers

visit

our

factory

and

check

the

machine,

we

will

teach

you

how

to

install

and

use

the

machine,

and

also

train

your

workers/technician

face

to

face.

Without

visiting,we

will

send

you

user

manual

and

video

to

teach

you

to

install

and

operate.

If buyer needs our technician to go to your local factory,please arrange board and lodging and other necessary things.

Packing Detall

1.

one

40ft

container

for

loading

one

set

machine

with

manual

decoiler;

2.

the

whole

Wiped

Anti

Rust

Oil,

PLC

controller

covered

by

foam

film;

3.

Spare

parts

and

some

small

parts

packed

in

plastic

tooling

box;

4.

All

Components

Fixed

by

steel

wire

with

Container.

Other Product

Specializing in the production of automatic c-beam machine, CZ steel machine, roof panel equipment swap, LouCheng board equipment, glazed tile,high-speed guardrail equipment, double caigang watts, doors equipment , light steel keel equipment, solar photovoltaic equipment, water stop plate equipment, rail fence equipment, cullis sink devices, automatic doors, ridge tile equipment, sandwich composite machine, shearing machine, bending machine, slitting machine other caigang watts and cold bending forming equipment.