| Price | by case |

| MOQ | 1 |

| Delivery Time | 2-4 weeks |

| Brand | ZMSH |

| Place of Origin | China |

| Model Number | sapphire seed |

| Packaging Details | custom cartons |

| Payment Terms | T/T |

| Supply Ability | By case |

| Place of Origin | China | Packaging Details | custom cartons |

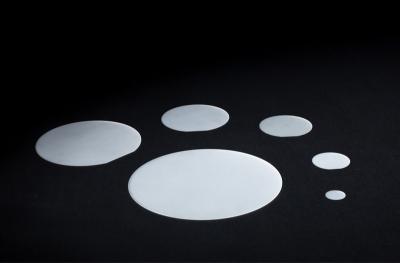

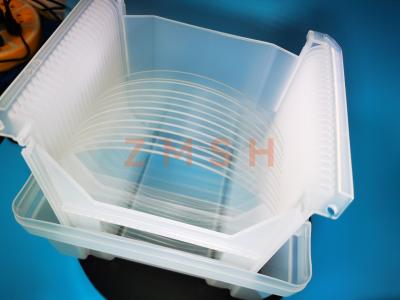

| Product Name | Sapphire Square Seed Crystal | Tolerance | ±0.01 mm |

| Crystal Orientation | A-plane, C-plane, M-plane, R-plane | Model Number | sapphire seed |

| Hardness | 9.0 | Supply Ability | By case |

| Brand Name | ZMSH | Payment Terms | T/T |

| Price | by case | Delivery Time | 2-4 weeks |

| Length | 50 – 120 mm | Size Options | 10 × 10 mm / 12 × 12 mm / Custom sizes available |

| Minimum Order Quantity | 1 |

Sapphire seed crystals are small, highly refined single crystals of aluminum oxide (Al₂O₃) that serve as the indispensable starting material for the production of synthetic sapphire. In sapphire growth, the seed crystal functions as a “blueprint,” guiding the development of a new sapphire boule by dictating the lattice structure, orientation, and overall quality of the growing crystal. Without these seeds, large-scale production of uniform and defect-free sapphire would be virtually impossible.

Because sapphire is widely used in advanced industries—from LED substrates and semiconductor wafers to aerospace optics and luxury watch crystals—the seed crystal plays a strategic role in ensuring that the synthetic sapphire produced meets the highest optical, mechanical, and structural standards. Each seed crystal is carefully crafted, inspected, and selected to withstand the extreme temperatures and demanding conditions of sapphire growth furnaces.

The production of sapphire seed crystals is a precision-controlled process that requires expertise and specialized equipment. The steps include:

Selection of Master Sapphire Boule – The process begins with a large, defect-free synthetic sapphire boule, produced by established growth methods. Only boules with minimal stress, low dislocation density, and high purity (99.99% or higher) qualify for seed production.

Crystallographic Orientation – Using X-ray orientation systems, technicians determine the precise crystallographic planes within the boule. Common orientations include C-plane , A-plane , and R-plane . The correct orientation is essential, as it defines the direction in which the new sapphire boule will expand.

Precision Cutting – Ultra-thin diamond saws or laser systems cut the boule into small plates, rods, or blocks along the chosen orientation. Accuracy at this stage is critical—an error of even a fraction of a degree can lead to lattice mismatch during growth.

Polishing and Surface Treatment – The cut Sapphire seed crystals pieces undergo multiple stages of fine grinding, lapping, and chemical-mechanical polishing (CMP). This step removes subsurface damage and ensures an atomically smooth surface, enabling flawless lattice continuation during crystal growth.

Cleaning and Quality Control – The Sapphire seed crystals are cleaned in chemical baths to remove any contaminants. Advanced inspection methods (optical microscopy, X-ray topography) verify orientation, purity, and absence of inclusions or cracks. Only those that pass stringent testing become certified sapphire seeds for crystal growth.

Ultra-high purity – Typically ≥99.99% Al₂O₃, ensuring the sapphire grown from the seed is optically clear and structurally stable.

Precisely defined orientation – Enables uniform lattice alignment and consistent crystal properties.

Thermal durability – Resistant to temperatures over 2,000°C, necessary for contact with molten alumina.

Low dislocation density – Reduces imperfections, cracks, and optical defects in the final sapphire boule.

Customizable geometry – Available in wafer form, small blocks, or rods depending on the specific growth method.

These attributes make sapphire seed crystals the single most important factor in determining the quality of the sapphire boule produced.

| Item | Specification |

|---|---|

| Product Name | Sapphire Seed Crystal Square |

| Length | 50 – 120 mm |

| Size Options | 10 × 10 mm / 12 × 12 mm / Custom sizes available |

| Tolerance | ±0.01 mm |

| Crystal Orientation | A-plane, C-plane, M-plane, R-plane |

The primary and almost exclusive use of sapphire seed crystals is to enable the production of synthetic sapphire, and they are absolutely indispensable in nearly all modern sapphire growth techniques. Each method uses the seed crystal in a slightly different way, but the principle remains the same: the seed crystal dictates the lattice orientation of the sapphire boule that grows from it, ensuring uniformity and preventing random crystallization.

Sapphire seed crystal is the most widely used method for producing sapphire for LED substrates and optical components. In the KY process, the sapphire seed crystal is carefully dipped into a crucible containing molten aluminum oxide (Al₂O₃) at temperatures exceeding 2,000°C. By precisely controlling the cooling rate, sapphire begins to solidify on the seed’s surface, expanding outward into a large, low-stress boule. Because the seed defines the crystal orientation, the resulting sapphire boule maintains a consistent lattice structure, which is essential for downstream wafer slicing and polishing.

In the CZ process, a Sapphire seed crystal is attached to a pulling rod and gently immersed into the molten alumina. The Sapphire seed crystals is slowly lifted and rotated, drawing up a column of sapphire that grows continuously from the seed’s lattice. This method allows for extremely tight control over diameter and uniformity, which is crucial for high-precision optical sapphire and specialty components. Without a perfectly oriented seed, the crystal would twist or develop internal stresses that make it unsuitable for demanding applications.

HEM also relies on a sapphire seed crystal to initiate growth. Here, the seed is placed at the base of the crucible, and the furnace is cooled from the bottom up. Sapphire forms as the heat dissipates, growing upwards from the seed. Because the temperature gradient is gentle, HEM can produce very large sapphire blocks with minimal internal stress and excellent transparency — ideal for aerospace windows, laser systems, and scientific optics.

Unlike KY and CZ, which produce boules, the EFG method uses the Sapphire seed crystals to grow sapphire in special shapes. The seed is positioned at the edge of a mold, and molten alumina feeds the seed by capillary action. As the seed pulls the material upwards, sapphire grows into rods, ribbons, tubes, or rings with the same orientation as the seed. This process would not be possible without a seed crystal, as uncontrolled crystal growth would result in distortion or breakage.

Q1:

Why

are

sapphire

seed

crystals

necessary?

A1:

They

define

the

crystal

orientation

and

lattice

structure

of

the

growing

sapphire

boule.

Without

a

seed,

the

crystal

would

grow

randomly,

resulting

in

defects,

cracks,

and

poor

optical

quality.

Q2:

Can

a

single

Sapphire

seed

crystal be

reused?

A2:

Some

seed

crystals

can

be

reused

a

few

times,

but

repeated

use

increases

the

risk

of

contamination

and

lattice

distortion.

Most

manufacturers

prefer

fresh

seeds

for

critical

growth

operations.

Q3:

What

orientations

are

available?

A3:

The

most

common

orientations

are

C-plane

(for

LED

substrates),

A-plane,

and

R-plane,

but

custom

orientations

can

be

prepared

for

specialized

needs.

Q4:

Which

sapphire

growth

methods

need

seed

crystals?

A4:

Almost

every

modern

method—KY,

CZ,

HEM,

and

EFG—depends

on

seed

crystals.

Only

the

outdated

Verneuil

method

does

not.

Q5:

What

industries

indirectly

depend

on

seed

crystals?

A5:

Any

industry

that

uses

synthetic

sapphire—LED

lighting,

semiconductor

electronics,

aerospace

optics,

luxury

watches—relies

on

sapphire

grown

from

seed

crystals.

Related Products

Sapphire Al2O3 Ingots 80KG 200KG 400KG KY Growth Method For Sapphire Component Processing

Sapphire wafer 2inch C-plane(0001) DSP SSP 99,999% Monocrystalline Al2O3 LEDS Semiconductor

ZMSH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.