| Price | BY case |

| MOQ | 3PCS |

| Delivery Time | 2-6weeks |

| Brand | ZMSH |

| Place of Origin | CN |

| Certification | ROHS |

| Model Number | S-C-N |

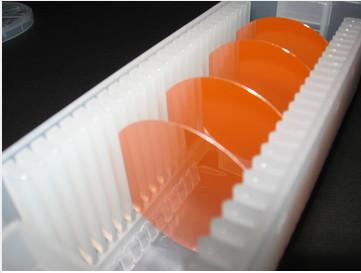

| Packaging Details | single wafer container under cleaning room |

| Payment Terms | T/T, Western Union |

| orientation | 100 2°off | Place of Origin | CN |

| Shape | with Notch | surface | SSP |

| thickness | 675±25um | Packaging Details | single wafer container under cleaning room |

| Material | GaAs crystal | bow | 10um |

| Model Number | S-C-N | Certification | ROHS |

| Brand Name | ZMSH | Payment Terms | T/T, Western Union |

| growth method | VGF | size | 6inch |

| Price | BY case | Delivery Time | 2-6weeks |

| Minimum Order Quantity | 3PCS | TTV | 10UM |

| EPD | <500 | Dopant | Si-doped |

VGF 2inch 4inch 6inch n-type prime grade GaAs wafer for epitaxial growth

GaAs wafer (Gallium Arsenide) is an advantageous alternative to silicon that has been evolving in the semiconductor industry. Less power consumption and more efficiency offered by this GaAs wafers are attracting the market players to adopt these wafers, thereby increasing the demand for GaAs wafer. Generally, this wafer is used to manufacture semiconductors, light emitting diodes, thermometers, electronic circuits, and barometers, besides finding application in the manufacturing of low melting alloys. As the semiconductor and electronic circuit industries continue to touch new peaks, the GaAs market is booming. Gallium arsenide of GaAs wafer has the power of generating laser light from electricity. Especially polycrystalline and single crystal are the two major type of GaAs wafers, which are utilized in the production of both the microelectronics and optoelectronics to create LD, LED, and microwave circuits. Therefore, the extensive range of GaAs applications, particularly in optoelectronics and microelectronics industry is creating a demand influx in the GaAs Wafer Market. Previously, the optoelectronic devices were mainly used on a broad range in short-range optical communications and computer peripherals. But now, they are in demand for some emerging applications such as LiDAR, augmented reality, and face recognition. LEC and VGF are two popular methods which are improving the production of GaAs wafer with high uniformity of electrical properties and excellent surface quality. Electron mobility, single junction band-gap, higher efficiency, heat and moisture resistance, and superior flexibility are the five distinct advantages of GaAs, which are improving the acceptance of GaAs wafers in the semiconductor industry.

What we provide:

|

Item

|

Y/N

|

Item

|

Y/N

|

Item

|

Y/N

|

|

GaAs

crystal

|

yes

|

Electronic

Grade

|

yes

|

N

type

|

yes

|

|

GaAs

blank

|

yes

|

Infrared

Grade

|

yes

|

P

type

|

yes

|

|

GaAs

substrate

|

yes

|

Cell

Grade

|

yes

|

Undoped

|

yes

|

|

GaAs

epi

wafer

|

yes

|

||||

| GaAs (Gallium Arsenide) for LED Applications | ||

| Item | Specifications | Remarks |

| Conduction Type | SC/n-type | |

| Growth Method | VGF | |

| Dopant | Silicon | |

| Wafer Diamter | 2, 3 & 4 inch | Ingot or as-cut available |

| Crystal Orientation | (100)2°/6°/15° off (110) | Other misorientation available |

| OF | EJ or US | |

| Carrier Concentration | (0.4~2.5)E18/cm3 | |

| Resistivity at RT | (1.5~9)E-3 Ohm.cm | |

| Mobility | 1500~3000 cm2/V.sec | |

| Etch Pit Density | <500/cm2 | |

| Laser Marking | upon request | |

| Surface Finish | P/E or P/P | |

| Thickness | 220~350um | |

| Epitaxy Ready | Yes | |

| Package | Single wafer container or cassette | |

|

GaAs (Gallium Arsenide) ,Semi-insulating for Microelectronics Applications

|

||

|

Item

|

Specifications

|

Remarks

|

|

Conduction

Type

|

Insulating

|

|

|

Growth

Method

|

VGF

|

|

|

Dopant

|

Undoped

|

|

|

Wafer

Diamter

|

2,

3,

4

&

6

inch

|

Ingot

available

|

|

Crystal

Orientation

|

(100)+/-

0.5°

|

|

|

OF

|

EJ,

US

or

notch

|

|

|

Carrier

Concentration

|

n/a

|

|

|

Resistivity

at

RT

|

>1E7

Ohm.cm

|

|

|

Mobility

|

>5000

cm2/V.sec

|

|

|

Etch

Pit

Density

|

<8000

/cm2

|

|

|

Laser

Marking

|

upon

request

|

|

|

Surface

Finish

|

P/P

|

|

|

Thickness

|

350~675um

|

|

|

Epitaxy

Ready

|

Yes

|

|

|

Package

|

Single

wafer

container

or

cassette

|

|

| No. | Item | Standard Specification | |||||

| 1 | Size | 2" | 3" | 4" | 6" | ||

| 2 | Diameter | mm | 50.8±0.2 | 76.2±0.2 | 100±0.2 | 150±0.5 | |

| 3 | Growth Method | VGF | |||||

| 4 | Doped | Un-doped, or Si-doped, or Zn-doped | |||||

| 5 | Conductor Type | N/A, or SC/N, or SC/P | |||||

| 6 | Thickness | μm | (220-350)±20 or (350-675)±25 | ||||

| 7 | Crystal Orientation | <100>±0.5 or 2 off | |||||

| OF/IF Orientation Option | EJ, US or Notch | ||||||

| Orientation Flat (OF) | mm | 16±1 | 22±1 | 32±1 | - | ||

| Identification Flat (IF) | mm | 8±1 | 11±1 | 18±1 | - | ||

| 8 | Resistivity |

(Not

for Mechanical Grade) |

Ω.cm | (1-30)´107, or (0.8-9)´10-3, or 1´10-2-10-3 | |||

| Mobility | cm2/v.s | ≥ 5,000, or 1,500-3,000 | |||||

| Carrier Concentration | cm-3 |

(0.3-1.0)x1018,

or

(0.4-4.0)x1018, or As SEMI |

|||||

| 9 | TTV | μm | ≤10 | ||||

| Bow | μm | ≤10 | |||||

| Warp | μm | ≤10 | |||||

| EPD | cm-2 | ≤ 8,000 or ≤ 5,000 | |||||

| Front/Back Surface | P/E, P/P | ||||||

| Edge Profile | As SEMI | ||||||

| Particle Count |

<50

(size>0.3

μm,count/wafer), or AS SEMI |

||||||

| 10 | Laser Mark | Back side or upon request | |||||

| 11 | Packaging | Single wafer container or cassette | |||||

Package Detail: