| Price | USD1000~USD1200 per ton |

| MOQ | 1 |

| Delivery Time | 30 days |

| Brand | FAMOUS |

| Place of Origin | China |

| Certification | ISO9001 |

| Model Number | CB100(321-Type)&HD200 |

| Packaging Details | seaworthy packings for container shipping |

| Payment Terms | L/C, T/T, D/A, D/P, Western Union |

| Supply Ability | 10000 units per year |

| Place of Origin | China | Place of origin | Hangzhou, China |

| Packaging Details | seaworthy packings for container shipping | Color | light gray |

| Dimensions | Standard | Standard | River Crossing Bridge |

| Grade | Q345B-Q460C | Model Number | CB100(321-Type)&HD200 |

| Supply Ability | 10000 units per year | Certification | ISO9001 |

| Brand Name | FAMOUS | Payment Terms | L/C, T/T, D/A, D/P, Western Union |

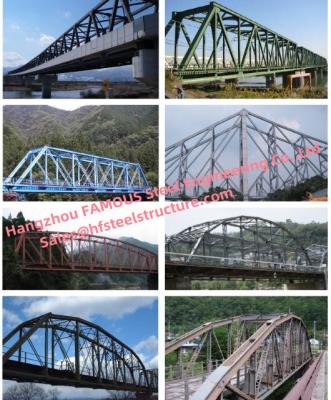

| Type | Modular Deck -type Assembly Steel Bridges | Price | USD1000~USD1200 per ton |

| Delivery Time | 30 days | Minimum Order Quantity | 1 |

| Application | Temporary or Permanent Steel Structure Bridge |

Description of Portable Floating Bridge

Floating bridges are uncommon in large part because the kinds of situations and environmental criteria for them are unusual. These bridges are mostly needed to connect heavily populated areas where there is a very wide and very deep body of water, along with extremely soft lake- or ocean-bottom soil, factors that prohibit conventional bridge piers (the structure on which the bridge surface rests). They are cost-effective in comparison to traditional bridges in scenarios where the water is more than 100 feet (30 meters) deep, and a half mile (900 meters) wide.

Specification of Portable Floating Bridge

| Product Name | Portable floating bridge |

| Width | 3.7m |

| Maximum span | 64meter single span and 200meter multi span |

| Bridge deck | Steel composit panel |

| Steel grade | Q345B (equivalent to ASTM A572) |

| Loading capacity | 20ton, 40ton truck etc, or HS20-44, HS25-44/Truck 20 |

| Corrosion | Original painted or Hot dip galvanized |

| Advantages | Price effective and technical full analysis and supports |

Application

The floating bridge can be used for pedestrian, road and railway. The structure is not complicated, and the racking is convenient, but the maintenance cost is high. It can be used as an emergency rescue facility or as a temporary transportation facility. It can be used in wartime to ensure that the army can quickly pass through the military floating bridge. In order to increase its mobility, it is usually made of light metal.

Features

and

Benefits

Heavy

duty

loading

Galvanized

steel

deck

Lengths

from

6.1

m

(20′)

to

24.4

m

(80′)

Clear

spans

up

to

45.7

m

(150′)

Single

or

multiple

lane

widths

Bearing

plates

and

pads

Curb

system

Timber

running

planks

Advantage

Floating

bridges

can

offer

advantages

over

fixed

bridges

in

a

number

of

ways.

A

floating

bridge

is

something

that

can

be

put

into

place

quickly,

and

they

are

also

inexpensive

in

terms

of

cost.

A

modern

floating

bridge

can

also

offer

the

type

of

durability

associated

with

a

fixed

bridge.

Floating

bridges

can

be

utilized

with

pedestrians

in

mind,

and

are

capable

of

coping

with

vehicles.

Floating

bridges

are

safe,

and

floating

bridges

are

becoming

more

of

a

long

term

feature

in

some

countries

around

the

world.

Because

floating

bridges

can

be

modular

they

can

also

be

easily

extended,

which

helps

to

make

them

cost

effective.

In

addition,

the

low

maintenance

involved

with

a

floating

bridge

is

another

reason

why

they

are

a

good

option

for

many

local

authorities

to

consider.

How

do

floating

bridges

float?

Floating

bridges

are

made

of

large

water-tight

concrete

pontoons

connected

rigidly

end-to-end,

upon

which

the

roadway

is

built.

Despite

their

heavy

concrete

composition,

the

weight

of

the

water

displaced

by

the

pontoons

is

equal

to

the

weight

of

the

structure

(including

all

traffic),

which

allows

the

bridge

to

float.

Our company

Our experienced team is focused on your steel bridge project's success, from start to finish. Our proven ability to identify and overcome design inconsistencies, potential problems with erection, and shipping obstacles results in the fabrication of structural steel that is right the first time, helping you avoid costly construction delays.

Proper project coordination and efficient delivery of the structural steel to your bridge project is a key factor in its ultimate success. This is what gives us the leading edge.

From material purchase and tracing, planning compilation, drawing detailing, production arrangement, quality inspection, to on-going painting, packing and delivering, we have separated department to strictly control process, quality and traceability, so that the perfect Bailey/Belay/Baley Bridge can be made.

Finally we would like to emphasize that not like other companies, nearly all machining parts and mechanical accessories are manufactured in our own shop as we have so many wonderful machines and workers inside. In this way, the quality, cost and delivery time can be ensured which eliminates other exterior factors’ influence.

Warmly welcome all friends and clients from International market to visit us!