Immersion

Silver

PCB

on

0.4mm

FR-4

ITEQ

4

Layer

Circuit

Board

for

Security

Systems

1.1

General

description

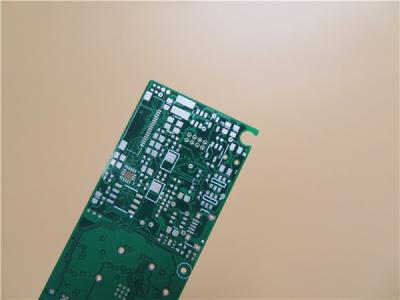

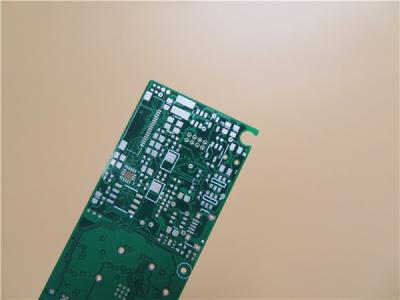

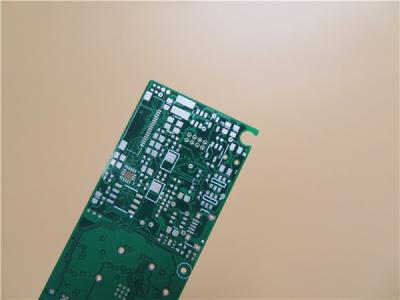

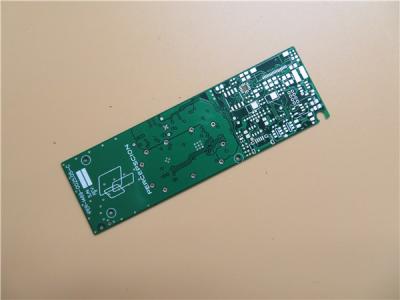

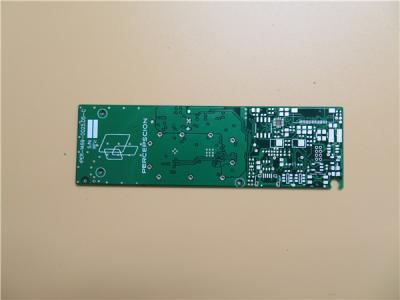

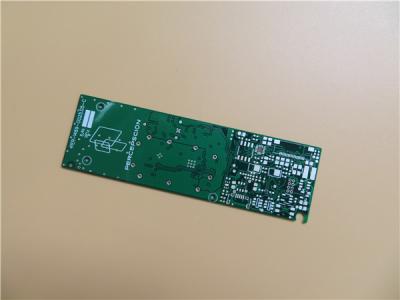

This

is

a

type

of

4

layer

printed

circuit

board

built

on

FR-4

substrate

with

mid-Tg

150°C

for

the

application

of

Security

Systems.

It's

only

0.4

mm

thick

with

white

silkscreen(Taiyo)

on

green

solder

mask

(Nanya)

and

immersion

silver

on

pads.

The

base

material

is

from

Taiwan

ITEQ

supplying

1

up

PCB

per

panel.

They're

fabricated

per

IPC

6012

Class

2

using

supplied

Gerber

data.

Each

30

boards

are

packed

for

shipment.

1.2

Features

and

benifits

Very

Low

Moisure

Absorption

and

better

CAF

resistance

Good

solderability

16000

square

meter

workshop

Meeting

your

PCB

needs

from

prototype

to

mass

production.

UL

recognized

and

RoHS

Directive-compliant

Customer

complaint

rate:

<1%

1.3

Applications

Medium

Access

Control

Speaker

System

Broadband

Modem

Vfd

Drive

Module

GSM

Gate

Access

Control

1.4

Parameter

and

data

sheet

|

PCB

SIZE

|

111

x

45mm=1PCS

|

|

BOARD

TYPE

|

Multilayer

PCB

|

|

Number

of

Layers

|

4

Layers

|

|

Surface

Mount

Components

|

YES

|

|

Through

Hole

Components

|

YES

|

|

LAYER

STACKUP

|

copper

-------

18um(0.5oz)+plate

TOP

layer

|

|

PP

2116

x

1

|

|

copper

-------

18um(0.5oz)

|

|

FR-4

0.1mm

|

|

copper

-------

18um(0.5oz)

|

|

PP

2116

x

1

|

|

copper

-------

18um(0.5oz)+plate

BOT

Layer

|

|

TECHNOLOGY

|

|

|

Minimum

Trace

and

Space:

|

6.99mil/8.47mil

|

|

Minimum

/

Maximum

Holes:

|

0.399mm/3.556mm

|

|

Number

of

Different

Holes:

|

7

|

|

Number

of

Drill

Holes:

|

1521

|

|

Number

of

Milled

Slots:

|

0

|

|

Number

of

Internal

Cutouts:

|

0

|

|

Impedance

Control

|

no

|

|

BOARD

MATERIAL

|

|

|

Glass

Epoxy:

|

FR-4,

ITEQ

IT-158,

Tg>150

°C

|

|

Final

foil

external:

|

1oz

|

|

Final

foil

internal:

|

0.5oz

|

|

Final

height

of

PCB:

|

0.5mm

±0.1

|

|

PLATING

AND

COATING

|

|

|

Surface

Finish

|

Immersion

Silver,

Ag>0.15µm

|

|

Solder

Mask

Apply

To:

|

Top

and

Bottom,

12micon

Minimum.

|

|

Solder

Mask

Color:

|

Green,

LP-4G

G-05,

Nanya

supplied

|

|

Solder

Mask

Type:

|

LPSM

|

|

CONTOUR/CUTTING

|

Routing

|

|

MARKING

|

|

|

Side

of

Component

Legend

|

TOP

|

|

Colour

of

Component

Legend

|

White,

S-380W,

Taiyo

Supplied.

|

|

Manufacturer

Name

or

Logo:

|

Marked

on

the

board

in

a

conductor

and

leged

FREE

AREA

|

|

VIA

|

Plated

Through

Hole(PTH),

via

tented.

|

|

FLAMIBILITY

RATING

|

UL

94-V0

Approval

MIN.

|

|

DIMENSION

TOLERANCE

|

|

|

Outline

dimension:

|

0.0059"

(0.15mm)

|

|

Board

plating:

|

0.0030"

(0.076mm)

|

|

Drill

tolerance:

|

0.002"

(0.05mm)

|

|

TEST

|

100%

Electrical

Test

prior

shipment

|

|

TYPE

OF

ARTWORK

TO

BE

SUPPLIED

|

email

file,

Gerber

RS-274-X,

PCBDOC

etc

|

|

SERVICE

AREA

|

Worldwide,

Globally.

|

![]()

1.5

ITEQ

Laminate/

Prepreg

:

IT-140TC

/

IT-140BS

|

Property

|

Thickness<0.50

mm

|

Thickness≧0.50

mm

|

Units

|

Test

Method

|

|

[0.0197

in]

|

[0.0197

in]

|

|

Typical

Value

|

Spec

|

Typical

Value

|

Spec

|

Metric

|

IPC-TM-650

|

|

(English)

|

(or

as

noted)

|

|

Peel

Strength,

minimum

|

|

|

|

|

N/mm

|

2.4.8

|

|

A.

Low

profile

copper

foil

and

very

low

profile

copper

foil

-

all

copper

weights

>

17mm

[0.669

mil]

|

|

|

|

|

(lb/inch)

|

2.4.8.2

|

|

B.

Standard

profile

copper

foil

|

0.96

(5.5)

|

0.70

(4.0)

|

0.96

(5.5)

|

0.70

(4.0)

|

|

2.4.8.3

|

|

1.

After

Thermal

Stress

|

|

|

|

|

|

|

|

2.

At

125°C

[257

F]

|

|

|

|

|

|

|

|

3.

After

Process

Solutions

|

1.75

(10

)

|

0.80

(4.57)

|

1.93

(11.0)

|

1.05

(6.00)

|

|

|

|

|

1.66

(9.5)

|

0.70

(4.00)

|

1.66

(9.5)

|

0.70

(4.00)

|

|

|

|

|

1.49

(8.5)

|

0.55

(3.14)

|

1.49

(8.5)

|

0.80

(4.57)

|

|

|

|

Volume

Resistivity,

minimum

|

|

|

|

|

MW-cm

|

2.5.17.1

|

|

A.

C-96/35/90

|

5x1010

|

106

|

--

|

--

|

|

B.

After

moisture

resistance

|

--

|

--

|

5x1010

|

104

|

|

C.

At

elevated

temperature

E-24/125

|

5x1010

|

103

|

5x1010

|

103

|

|

Surface

Resistivity,

minimum

|

|

|

|

|

MW

|

2.5.17.1

|

|

A.

C-96/35/90

|

3.5x1010

|

104

|

--

|

--

|

|

B.

After

moisture

resistance

|

--

|

--

|

3.5x1010

|

104

|

|

C.

At

elevated

temperature

E-24/125

|

6x1010

|

103

|

6x1010

|

103

|

|

Moisture

Absorption,

maximum

|

0.3

|

--

|

0.1

|

0.8

|

%

|

2.6.2.1

|

|

Dielectric

Breakdown,

minimum

|

--

|

--

|

60

|

40

|

kV

|

2.5.6

|

|

Permittivity

(Dk,

50%

resin

content)

|

4.6

|

5.4

|

4.6

|

5.4

|

--

|

2.5.5.9

|

|

(Laminate

&

Laminated

Prepreg)

|

|

A.

1MHz

|

|

Loss

Tangent

(Df,

50%

resin

content)

|

0.016

|

0.035

|

0.016

|

0.035

|

--

|

2.5.5.9

|

|

(Laminate

&

Laminated

Prepreg)

|

|

A.

1MHz

|

|

Flexural

Strength,

minimum

|

|

|

|

|

N/mm2

|

2.4.4

|

|

A.

Length

direction

|

--

|

--

|

500-530

|

415

|

(lb/in2)

|

|

|

--

|

--

|

(72,500-76,850)

|

-60,190

|

|

|

B.

Cross

direction

|

--

|

--

|

430-460

|

345

|

|

|

|

--

|

--

|

(62,350-66,700)

|

-50,140

|

|

|

Arc

Resistance,

minimum

|

120

|

60

|

120

|

60

|

s

|

2.5.1

|

|

Thermal

Stress

10

s

at

288°C

[550.4F],minimum

|

|

|

|

|

Rating

|

2.4.13.1

|

|

A.

Unetched

|

Pass

|

Pass

Visual

|

Pass

|

Pass

Visual

|

|

B.

Etched

|

Pass

|

Pass

Visual

|

Pass

|

Pass

Visual

|

|

Electric

Strength,

minimum

|

45

|

30

|

--

|

--

|

kV/mm

|

2.5.6.2

|

|

(Laminate

&

Laminated

Prepreg)

|

|

Flammability,

|

V-0

|

V-0

|

V-0

|

V-0

|

Rating

|

UL94

|

|

(Laminate

&

Laminated

Prepreg)

|

|

Glass

Transition

Temperature(DSC)

|

140

|

135

minimum

|

140

|

135

minimum

|

˚C

|

2.4.25

|

|

Decomposition

Temperature

|

--

|

--

|

305

|

--

|

˚C

|

2.4.24.6

|

|

(5%

wt

loss)

|

|

Z-Axis

CTE

|

|

|

|

|

|

2.4.24

|

|

A.

Alpha

1

|

--

|

--

|

55

|

--

|

ppm/˚C

|

|

B.

Alpha

2

|

--

|

--

|

290

|

--

|

ppm/˚C

|

|

C.

50

to

260

Degrees

C

|

--

|

--

|

4.2

|

--

|

%

|

|

Thermal

Resistance

|

|

|

|

|

|

2.4.24.1

|

|

A.

T260

|

--

|

--

|

15

|

--

|

Minutes

|

|

B.

T288

|

--

|

--

|

2

|

--

|

Minutes

|

|

CAF

Resistance

|

--

|

--

|

Pass

|

AABUS

|

Pass/Fail

|

2.6.25

|