Impedance

Controlled

PCB

Differential

Impedance

Circuit

Board

8

Layer

PCB

for

Wireless

HDMI

1.1

General

description

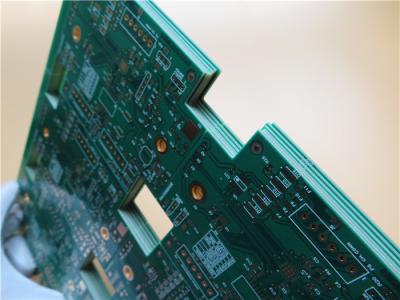

This

is

a

type

of

8

layer

printed

circuit

board

built

on

FR-4

substrate

with

Tg

170°C

for

the

application

of

Wireless

HDMI.

It's

1.6

mm

thick

with

white

silkscreen(Taiyo)

on

green

solder

mask

(Taiyo)

and

immersion

gold

on

pads.

It's

also

an

impedance

controlled

PCB

with

single-end

impedance

and

differential

impedance

controlled

on

on

top

layer

and

bottom

layer.

The

base

material

is

from

Taiwan

ITEQ

supplying

1

up

PCB

per

panel.

They're

fabricated

per

IPC

6012

Class

2

using

supplied

Gerber

data.

Each

25

panels

are

packed

for

shipment.

1.2

Features

and

benifits

Lead

free

assemblies

with

a

maximum

reflow

temperature

of

260℃

High

solderability,

no

stressing

of

circuit

boards

and

less

contamination

of

PCB

surface.

AOI

inspection

8000

types

of

PCB

per

month

12

hours

quotation

Free-of-charge

PCB

panelization

1.3

Applications

USB

Adapter

WiFi

USB

Dongle

GPRS

Modem

1.4

Parameter

and

data

sheet

|

PCB

SIZE

|

109.3

x

107.41mm=1PCS

|

|

BOARD

TYPE

|

Multilayer

PCB

|

|

Number

of

Layers

|

8

layers

|

|

Surface

Mount

Components

|

YES

|

|

Through

Hole

Components

|

YES

|

|

LAYER

STACKUP

|

copper

-------

18um(0.5oz)+plate

TOP

layer

|

|

Prepreg

7628(43%)

0.195mm

|

|

copper

-------

35um(1oz)

MidLayer

1

|

|

FR-4

0.2mm

|

|

copper

-------

35um(1oz)

MidLayer

2

|

|

Prepreg

7628(43%)

0.195mm

|

|

copper

-------

35um(1oz)

MidLayer

3

|

|

FR-4

0.2mm

|

|

copper

-------

35um(1oz)

MidLayer

4

|

|

Prepreg

7628(43%)

0.195mm

|

|

copper

-------

35um(1oz)

MidLayer

5

|

|

FR-4

0.2mm

|

|

copper

-------

35um(1oz)

MidLayer

6

|

|

Prepreg

7628(43%)

0.195mm

|

|

copper

-------

18um(0.5oz)+plate

BOT

Layer

|

|

TECHNOLOGY

|

|

|

Minimum

Trace

and

Space:

|

4mil/4mil

|

|

Minimum

/

Maximum

Holes:

|

0.3/6.19mm

|

|

Number

of

Different

Holes:

|

24

|

|

Number

of

Drill

Holes:

|

5158

|

|

Number

of

Milled

Slots:

|

0

|

|

Number

of

Internal

Cutouts:

|

0

|

|

Impedance

Control:

|

Single-Ended

Trace

Width:L1,

L3,

L6,

L8

4mils

---

50

ohm,

Differential

trace/space:

top

layer

5.1/6.0

mils

--

90

ohm,

5.1

/

8

mils

---

100

ohm,

L6

5.1

/

8

mils

---

100

ohm;

bottom

layer

5.1

mil

/6

mils

---

90

ohm,

5.1mils

/

8

mils

---

100

ohm

|

|

Number

of

Gold

finger:

|

0

|

|

BOARD

MATERIAL

|

|

|

Glass

Epoxy:

|

FR-4

TG170℃,

er<5.4.IT-180,

ITEQ

Supplied

|

|

Final

foil

external:

|

1oz

|

|

Final

foil

internal:

|

1oz

|

|

Final

height

of

PCB:

|

1.6mm

±0.16

|

|

PLATING

AND

COATING

|

|

|

Surface

Finish

|

Immersion

gold

(26.1%

)

0.05µm

over

3µm

nickel

|

|

Solder

Mask

Apply

To:

|

TOP

and

Bottom,

12micron

Minimum

|

|

Solder

Mask

Color:

|

Green,

PSR-2000GT600D,

Taiyo

Supplied.

|

|

Solder

Mask

Type:

|

LPSM

|

|

CONTOUR/CUTTING

|

Routing,

stamp

holes.

|

|

MARKING

|

|

|

Side

of

Component

Legend

|

TOP

and

Bottom.

|

|

Colour

of

Component

Legend

|

White,

IJR-4000

MW300,

Taiyo

Supplied.

|

|

Manufacturer

Name

or

Logo:

|

Marked

on

the

board

in

a

conductor

and

leged

FREE

AREA

|

|

VIA

|

Plated

through

hole(PTH),

Via

in

pad,

Resin

via

plug,

via

capped.

|

|

FLAMIBILITY

RATING

|

UL

94-V0

Approval

MIN.

|

|

DIMENSION

TOLERANCE

|

|

|

Outline

dimension:

|

0.0059"

(0.15mm)

|

|

Board

plating:

|

0.0030"

(0.076mm)

|

|

Drill

tolerance:

|

0.002"

(0.05mm)

|

|

TEST

|

100%

Electrical

Test

prior

shipment

|

|

TYPE

OF

ARTWORK

TO

BE

SUPPLIED

|

email

file,

Gerber

RS-274-X,

PCBDOC

etc

|

|

SERVICE

AREA

|

Worldwide,

Globally.

|

1.5

Characteristic

Impedance

The

characteristic

impedance

of

the

conductor

on

the

printed

circuit

board

is

an

important

indicator

of

the

circuit

design,

especially

in

the

PCB

design

of

high

frequency

circuit.

Whether

the

characteristic

impedance

of

the

conductor

is

consistent

and

matching

with

the

characteristic

impedance

required

by

the

device

or

signal

must

be

taken

into

consideration.

Therefore,

these

two

concepts

in

reliability

design

of

PCB

design

must

be

paid

attention.

There

will

be

a

variety

of

signal

transmission

in

the

conductor

of

circuit

board.

To

increase

the

rate

of

transmission,

it

must

increase

its

frequency.

Due

to

the

factors

of

the

circuit

itself

such

as

etching,

stack

thickness,

track

width

and

so

on

are

different,

it

will

cause

changes

of

the

impedance

value,

resulting

in

its

signal

distortion.

Therefore,

the

impedance

value

of

conductor

on

high-speed

circuit

board

should

be

controlled

within

a

certain

range,

known

as

the

"impedance

control".

The

factors

that

affect

the

impedance

of

the

PCB

wiring

are

mainly

the

width

of

the

copper

track,

the

thickness

of

the

copper

track,

the

dielectric

constant

of

the

dielectric,

the

thickness

of

the

dielectric,

the

thickness

of

the

pad,

the

path

of

the

ground

layer,

the

wires

around

the

wiring,

etc.

So

the

impedance

of

the

wiring

on

the

board

must

be

controlled

in

the

design

of

the

PCB

to

avoid

signal

reflection

and

other

electromagnetic

interference

and

signal

integrity

issues

as

far

as

possible,

to

guarantee

the

stability

of

the

actual

use

of

the

PCB

board.

You

can

refer

to

the

corresponding

empirical

formula

for

the

calculation

method

of

micro-strip

line

and

strip

line

impedance

on

PCB

board.

![]()