Differential

Impedance

Controlled

PCB

Single-End

Impedance

Circuit

Board

10

Layer

PCB

Board

Satellite

systems

1.1

General

description

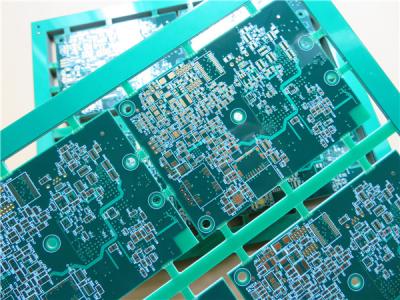

This

is

a

type

of

multilayer

PCB

built

on

FR-4

substrate

with

Tg

170°C

for

the

application

of

Satellite

systems

with

10

layer

copper.

It's

1.6

mm

thick

with

white

silkscreen(Taiyo)

on

green

solder

mask

(Taiyo)

and

immersion

gold

on

pads.

This

is

also

an

impedance

controlled

PCB

with

50

ohm

single-end

impedance

and

97

ohm

with

differential

impedance

control.

The

base

material

is

from

ITEQ

supplying

4

up

PCBs

per

panel.

They're

fabricated

per

IPC

6012

Class

2

using

supplied

Gerber

data.

Each

25

panels

are

packed

for

shipment.

1.2

Features

and

benifits

Lead

free

assemblies

with

a

maximum

reflow

temperature

of

260℃

SMT

process

is

resistant

to

reflow

soldering,

resistant

to

rework.

The

signal

lines

form

a

constant

low

impedance

to

the

ground

Strict

WIP

inspection

and

monitoring

as

well

as

working

instruction

UL,

ISO14001,

TS16949

certified

Hassle-free,

one-to-one

after-sales

service

Delivery

on

time:

>98%

1.3

Applications

GPS

Tracking

Devices

GSM

Signal

Booster

Automotive

dashboards

1.4

Parameter

and

data

sheet

|

PCB

SIZE

|

199

x

170mm=4PCS

|

|

BOARD

TYPE

|

Multilayer

PCB

|

|

Number

of

Layers

|

10

layers

|

|

Surface

Mount

Components

|

YES

|

|

Through

Hole

Components

|

YES

|

|

LAYER

STACKUP

|

copper

-------

18um(0.5oz)+plate

TOP

layer

|

|

Prepreg

0.1016mm

(4mil)

|

|

copper

-------

35um(1oz)

Plane

GND

|

|

FR-4

0.127mm

(5

mil)

|

|

copper

-------

18um(0.5

oz)

Signal

SIG1

|

|

Prepreg

0.127

mm

(5mil)

|

|

copper

-------

18um(0.5

oz)

Signal

SIG2

|

|

Prepreg

0.127mm

(5

mil)

|

|

copper

-------

35um(1oz)

Plane

PWR

|

|

FR-4

0.330mm

(13mil)

|

|

copper

-------

35um(1oz)

Plane

GND

|

|

Prepreg

0.127mm

(5

mil)

|

|

copper

-------

18

um(0.5

oz)

Signal

SIG3

|

|

Prepreg

0.127mm

(5

mil)

|

|

copper

-------

18

um(0.5

oz)

Signal

SIG4

|

|

Prepreg

0.127mm

(5

mil)

|

|

copper

-------

35um(1oz)

Plane

GND

|

|

Prepreg

0.1016mm

(4mil)

|

|

copper

-------

35um(1oz)

Signal

BOT

|

|

TECHNOLOGY

|

|

|

Minimum

Trace

and

Space:

|

4mil/4mil

|

|

Minimum

/

Maximum

Holes:

|

0.25/4.2mm

|

|

Number

of

Different

Holes:

|

15

|

|

Number

of

Drill

Holes:

|

850

|

|

Number

of

Milled

Slots:

|

10

|

|

Number

of

Internal

Cutouts:

|

0

|

|

Impedance

Control:

|

YES.

Top

layer,

7.0

mil

trace

50

ohms

single

end.

Layer

3

signal

layer,

4.0/4.0

mil

trace-space

differential

impedance

=

91

ohms;

4.0/6.0

mil

trace-space

differential

impedance

=

97

ohms.

|

|

Number

of

Gold

finger:

|

0

|

|

BOARD

MATERIAL

|

|

|

Glass

Epoxy:

|

FR-4

TG170℃,

er<5.4.IT-180,

ITEQ

Supplied

|

|

Final

foil

external:

|

1oz

|

|

Final

foil

internal:

|

1oz

|

|

Final

height

of

PCB:

|

1.6mm

±0.16

|

|

PLATING

AND

COATING

|

|

|

Surface

Finish

|

Immersion

gold

(30.1%

)

0.1µm

over

3µm

nickel

|

|

Solder

Mask

Apply

To:

|

TOP

and

Bottom,

12micron

Minimum

|

|

Solder

Mask

Color:

|

Green,

PSR-2000

KX700G,

Taiyo

Supplied.

|

|

Solder

Mask

Type:

|

LPSM

|

|

CONTOUR/CUTTING

|

Routing,

stamp

holes.

|

|

MARKING

|

|

|

Side

of

Component

Legend

|

TOP

and

Bottom.

|

|

Colour

of

Component

Legend

|

White,

S-380W,

Taiyo

Supplied.

|

|

Manufacturer

Name

or

Logo:

|

Marked

on

the

board

in

a

conductor

and

leged

FREE

AREA

|

|

VIA

|

plated

through

hole(PTH),

minimum

via

10

mils.

|

|

FLAMIBILITY

RATING

|

UL

94-V0

Approval

MIN.

|

|

DIMENSION

TOLERANCE

|

|

|

Outline

dimension:

|

0.0059"

|

|

Board

plating:

|

0.0029"

|

|

Drill

tolerance:

|

0.002"

|

|

TEST

|

100%

Electrical

Test

prior

shipment

|

|

TYPE

OF

ARTWORK

TO

BE

SUPPLIED

|

email

file,

Gerber

RS-274-X,

PCBDOC

etc

|

|

SERVICE

AREA

|

Worldwide,

Globally.

|

![]()

1.5

Impedance

PCB-

Impedance

match

If

there

is

signal

transmission

in

the

circuit

board,

it

is

expected

to

be

smoothly

transmitted

from

the

sending

end

to

the

receiving

end

under

the

condition

of

minimum

energy

loss,

and

the

receiving

end

can

completely

absorbs

it

without

any

reflection.

To

achieve

this

kind

of

transmission,

the

impedance

of

the

circuit

must

be

equal

to

the

internal

impedance

of

the

sending

end,

which

is

called

"impedance

match."

So

when

the

signal

is

transmitted

in

the

PCB,

the

characteristic

impedance

of

the

PCB

board

must

be

matched

with

the

electronic

impedance

of

the

head

and

tail

components.

Once

the

impedance

value

exceeds

the

tolerance,

the

transmitted

signal

energy

will

be

reflected,

scattered,

attenuated

or

delayed,

resulting

in

incomplete

signal

and

signal

distortion.

Impedance

match

is

one

of

the

design

elements

when

designing

high-speed

PCB

circuits.

However,

the

impedance

value

is

absolutely

related

with

wiring

mode.

For

example,

whether

wiring

on

the

surface

layer

or

inner

layer,

the

distance

from

the

reference

power

layer

or

ground

layer,

the

width

of

wiring,

the

PCB

material,

etc.

will

affect

the

characteristic

impedance

of

wiring.

That

is

to

say,

the

impedance

value

can

be

determined

only

after

wiring

layout,

while

the

characteristic

impedance

produced

by

different

PCB

manufacturers

is

also

slightly

different.

The

wiring

layout

condition

of

impedance

discontinuity

cannot

be

completely

considered

in

general

simulation

software

due

to

the

limitation

of

the

circuit

model

or

the

mathematical

algorithm

used.

In

this

case,

only

some

temninators,

such

as

series

resistors,

can

be

reserved

on

the

schematic

diagram

to

mitigate

the

effect

of

discontinuous

wiring

impedance.

The

method

to

completely

solve

the

problem

is

still

trying

to

avoid

the

occurrence

of

impedance

discontinuities

when

wiring

layout.

![]()