| Price | Negotiable |

| MOQ | 1 Set |

| Delivery Time | 3 days after payment confirm |

| Brand | PCB Separator |

| Place of Origin | Dongguan China |

| Certification | CE ISO9001 |

| Model Number | SMTfly-1M |

| Packaging Details | plywood case |

| Payment Terms | T/T, L/C, Western Union,paypal |

| Supply Ability | 300 sets/month |

| Place of Origin | Dongguan China | Warranty | one year free |

| Blades | linear and round | Packaging Details | plywood case |

| Depaneling speed | based on operator skill level | Model Number | SMTfly-1M |

| Supply Ability | 300 sets/month | Certification | CE ISO9001 |

| Brand Name | PCB Separator | Payment Terms | T/T, L/C, Western Union,paypal |

| Type | manual driven | Delivery Time | 3 days after payment confirm |

| Price | Negotiable | Minimum Order Quantity | 1 Set |

| Blade material | use Japanese high speed steel | Power | 110/220V |

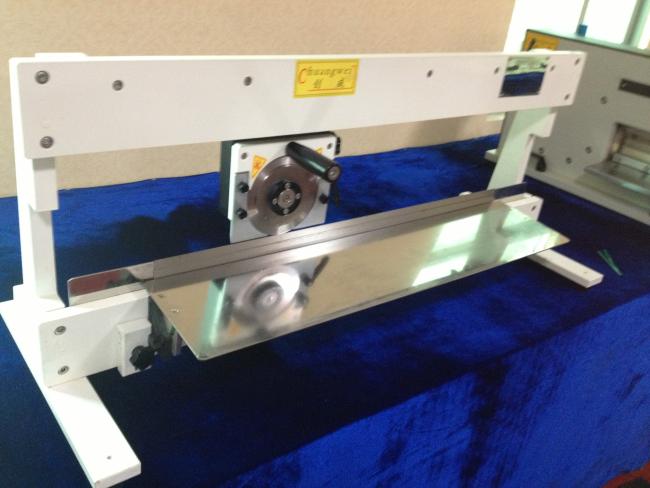

110V PCB Board Making Machine,0.6mm Thickness PCB Separator Machine,PCB Depaneling

Specification:

|

Model |

SMTfly-1M460 |

|

Max. PCB singulation length |

460mm |

|

PCB singulation Thickness |

0.6-3.5mm |

|

PCB singulation speed control |

by hand |

|

PCB singulation machine size |

787x400x436mm |

|

PCB singulation machine weight |

30Kg |

|

Model |

SMTfly-1M720 |

|

Max. PCB singulation length |

720mm |

|

PCB singulation thickness |

0.6-3.5mm |

|

PCB singulation speed control |

by hand |

|

PCB singulation machine size |

1027x400x436mm |

|

PCB singulation machine weight |

45kg |

Feature:

1. Round knife, manually cutting against lower linear knife, for reduced stress

2. Separate pre-scored PCB assembly without stress on either PCB or component

3. One touch programming of cut length with digital display

4. Separating speed is adjusted by a rotary knob

5. Handle Intermittent scoring or cut-outs

6. Board with projected component can be cut precisely

7. Large stainless steel platform on both side of cutting blade prevents board wobble and table height and angle are adjustable

8. Optional PCB conveyor belt to remove finished board

9. Clearance between circular and linear blades are adjustable to fit different groove depth and compensates for blade wear out

Competitive advantage:

1. SMTfly-1M Pcb depanelizer original manufacturers, price concessions

2. Day technical support services

3. Limit the handling of complaints, half an hour back to customers

4. Depanel Experts, the provision of professional PCB sub-programme

More information welcome to contact us:

Email:

sales@dgwill.com

Wechat/Whatsapp(Donna):

+86

15273473462