| Price | negotiable |

| MOQ | 1 set |

| Delivery Time | 3-7 work days |

| Brand | FANUC |

| Place of Origin | Japan |

| Certification | CE |

| Model Number | M-20iA |

| Payment Terms | L/C, T/T, D/A, D/P |

| Supply Ability | 100 |

| Place of Origin | Japan | Number of axes | 6 |

| Model Number | M-20iA | Supply Ability | 100 |

| Certification | CE | Weight | 250kg |

| Brand Name | FANUC | Payment Terms | L/C, T/T, D/A, D/P |

| Brand | FANUC | Repeatability | ±0.3mm |

| Price | negotiable | Delivery Time | 3-7 work days |

| Working range | 1811mm | Installation method | ground , ceiling , inclined angle |

| Minimum Order Quantity | 1 set | Model | FANUC M-20iA |

| Payload | 20kg |

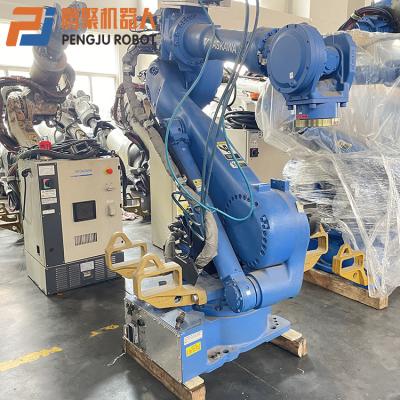

Used 6 Axis Industrial Robot FANUC 20iA Is Used For Automatic Laser Cutting Of Automobile Sheet Metal Parts

The M-20iA robot has a high-strength arm and advanced servo technology, which effectively improves the movement speed and acceleration and deceleration performance of each axis, shortens the working time of the movement by 15%, and realizes the highest production capacity in the industry. The robot wrist shaft is designed with an independent drive mechanism, which makes the robot arm slender and compact. It has a variety of arc welding functions to meet different welding needs, and the open robot interface can effectively meet the needs of different users.

There

are

models

with

a

hollow

wrist

for

easy

and

convenient

handling

of

user

cables,

and

models

with

a

wrist

with

a

high

allowable

moment

of

inertia

that

can

handle

large

workpieces.

You

can

choose

the

appropriate

model

from

the

standard

type,

short

arm

type,

and

long

arm

type

according

to

the

size

of

the

working

area.

Acceleration

and

deceleration

performance

has

been

improved

by

adopting

a

highly

rigid

arm

and

advanced

servo

control

technology.

Thereby

shortening

the

handling

time

and

improving

production

efficiency.

By

using

it

together

with

iRvision

(built-in

vision

function)

or

force

sensor,

various

latest

intelligent

functions

can

be

used.

Features

1.

The

movement

speed

of

each

axis

of

the

robot

is

fast,

which

ensures

that

the

working

time

of

the

movement

is

shortened

by

more

than

15%,

and

realizes

the

high

production

capacity

in

the

industry;

2.

The

robot

has

a

built-in

anti-collision

sensor,

and

no

external

mechanical

sensor

is

needed.

When

a

collision

occurs,

the

arm

will

bounce

up

quickly

to

ensure

the

safety

of

the

robot

and

surrounding

operators;

3.

The

robot

has

an

open

external

communication

and

I/O

interface,

which

can

be

matched

with

mainstream

welding

machines

at

home

and

abroad;

4.

Realize

digital

communication

between

the

robot

and

the

welding

power

source

to

ensure

the

coordinated

control

of

the

robot

and

the

welding

power

source

to

achieve

high-quality

welding;

5.

Can

realize

all-round

installation.

| Model | FANUC M-20iA |

| Place of origin | Japan |

| Mechanism | articulated robot |

| Number of axes | 6 axes |

| Working Range | 1811mm |

| Payload | 20kg |

| Repeatability | ±0.03mm |

| Body weight | 250kg |

| Installation method | ground installation, ceiling installation, inclined angle installation |

| Application fields | cutting, welding, handling, palletizing, loading and unloading, etc. |

| Condition | Used Fanuc Robot |

| After Sales Service | online service,video service |