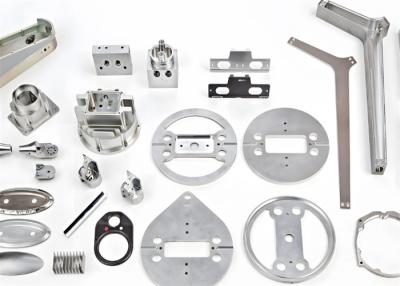

Product Description:

In

the

field

of

precision

machining

in

modern

manufacturing,

5-axis

CNC

machining

technology

is

becoming

a

key

force

for

many

industries

to

achieve

high-precision

and

high-efficiency

production

with

its

unparalleled

advantages.

It

breaks

through

the

limitations

of

traditional

machining

and

provides

a

perfect

solution

for

the

machining

of

workpieces

with

complex

shapes

and

high-precision

requirements.

Technical Principles and Advanced Features

The

5-axis

CNC

machining

system

integrates

three

linear

motion

axes

(X,

Y,

Z)

and

two

rotary

motion

axes

(usually

A

and

C

axes,

or

B

and

C

axes).

These

five

axes

can

move

in

coordination

under

the

precise

control

of

the

CNC

system,

enabling

the

tool

to

approach

the

workpiece

at

any

angle

and

direction,

realizing

all-round

machining.

Compared

with

traditional

3-axis

machining,

the

additional

rotary

axes

of

5-axis

CNC

machining

give

the

tool

more

flexible

attitude

adjustment

capabilities,

which

can

easily

handle

the

machining

of

workpieces

with

complex

curved

surfaces,

special-shaped

structures,

and

special

features

such

as

deep

cavities

and

undercuts.

Processing Advantages Show Excellent Quality

- High-precision machining guarantee: 5-axis CNC machining effectively reduces the cumulative error caused by multiple positioning by reducing the number of workpiece clamping times, significantly improving machining accuracy. When machining parts with extremely high precision requirements such as aero-engine blades and turbine disks, 5-axis CNC machining can ensure that key dimensional tolerances are controlled within a very small range, such as ±0.005mm, while achieving excellent surface finish, laying a solid foundation for the high-performance operation of products.

- Perfect presentation of complex shapes: With the powerful function of 5-axis linkage, it can easily realize the precise machining of complex curved surfaces and spatial curves. Whether it is complex structural parts in the aerospace field or fine parts in medical devices, 5-axis CNC machining can accurately transform the complex shapes in the design blueprint into physical objects, realizing a seamless connection from concept to product.

- Efficient machining improves productivity: 5-axis CNC machining can complete the machining of multiple surfaces in one clamping, greatly shortening the machining cycle and improving production efficiency. Compared with traditional machining methods, the machining time can be shortened by 30% - 50%, effectively reducing production costs and enhancing the market competitiveness of enterprises.

Widely Used in Diversified Industries

- Aerospace field: In the manufacturing of aero-engines, 5-axis CNC machining is used to process key components such as blades, casings, and disk parts, meeting the strict requirements for material removal rate, machining accuracy, and surface quality. At the same time, in the machining of aircraft structural parts, 5-axis CNC machining can realize the precise manufacturing of complex shapes, contributing to the lightweight design and high-performance improvement of aerospace products.

- Automotive manufacturing industry: In the manufacturing of auto parts, 5-axis CNC machining is widely used in the machining of complex parts such as engine blocks, cylinder heads, and transmission gears, improving machining accuracy and production efficiency, and providing a strong guarantee for the high performance and reliability of automobiles. Especially in the field of new energy vehicles, 5-axis CNC machining is of great significance for the machining of key components such as battery casings and motor casings.

- Medical device industry: Medical device products have extremely high requirements for precision and surface quality. 5-axis CNC machining can meet the machining needs of precision medical devices such as artificial joints, dental implants, and surgical instruments, ensuring the safety and reliability of products and contributing to the development of medical and health undertakings.

- Mold manufacturing field: In mold manufacturing, 5-axis CNC machining can realize efficient machining of complex parts such as mold cavities and cores, improving the manufacturing accuracy and surface finish of molds, shortening the mold manufacturing cycle, reducing production costs, and enhancing the market competitiveness of molds.

With

its

excellent

technical

performance,

high-precision

machining

capabilities,

and

wide

range

of

application

fields,

5-axis

CNC

machining

has

become

an

important

support

for

modern

manufacturing

to

achieve

transformation

and

upgrading

and

enhance

core

competitiveness.

Choosing

5-axis

CNC

machining

means

choosing

a

more

efficient,

more

precise,

and

more

competitive

machining

solution,

injecting

strong

impetus

into

your

product

manufacturing.