380v

2

Axis

CNC

Turning

Centre

Flat

Bed

GSK

Controller

Cnc

Lathe

Ck

6140

For

Metal

Key

Specifications

|

Number

Of

Axes

|

2/3/4

|

|

Coolant

System

|

Yes

|

|

Spindle

Bore

|

52mm

|

|

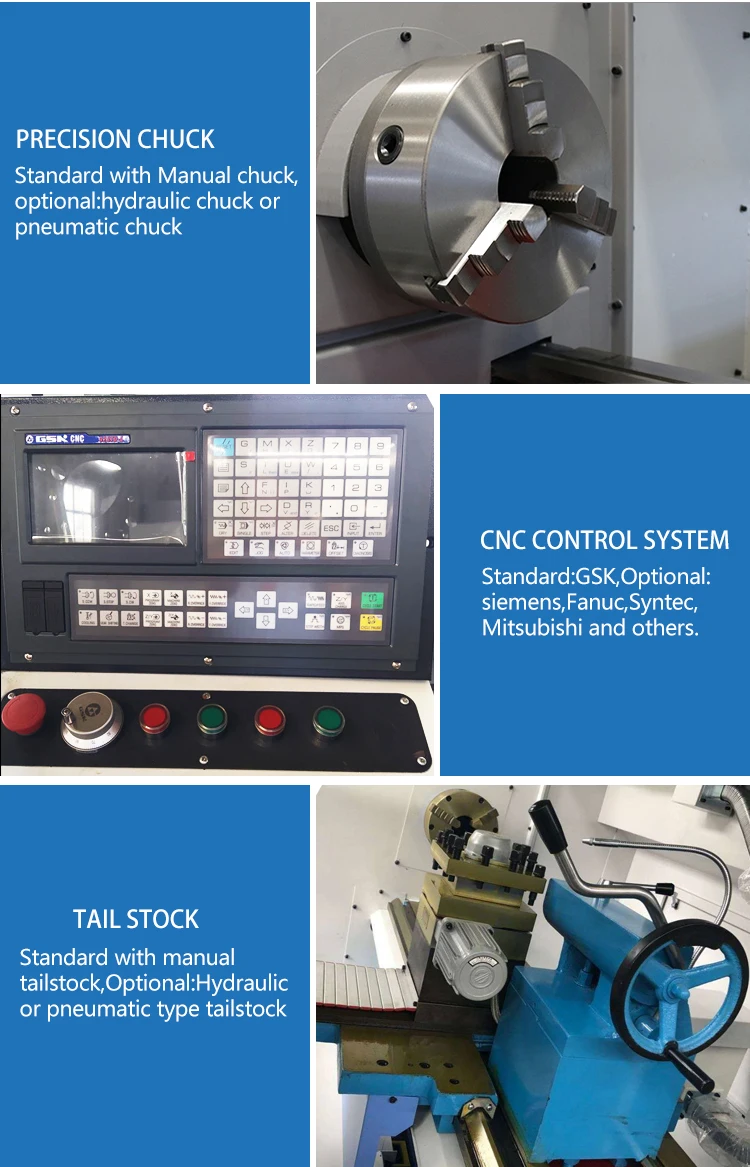

Precision

|

High

Precision

|

|

Spindle

Speed

|

150-2500rpm

|

|

Distance

Between

Centres

|

750/1000/1500/2000/3000mm

|

|

Positioning

Accuracy

|

0.01/0.015

|

|

Spindle

Taper

|

MT6

|

|

Tool

Bar

Section

|

20X20mm/25X25mm

|

|

Main

Motor

Power

|

5.5KW

|

Product

Overview

The

GSK

controller

flat-bed

380V

CNC

lathe

CK6140

is

a

high-precision

machine

designed

for

metalworking

applications.

Featuring

mechanical

and

electrical

integration

design,

it

offers

generous

appearance,

reasonable

structure,

and

easy

operation.

Key

Features:

-

Bed

casting

with

integrated

structure,

high

frequency

quenching

(5mm),

hardness

53-56

degrees

-

Guide

rail

with

two

artificial

aging

treatments,

surface

quenched

to

HRC50

hardness

-

45#

steel

forged

spindle

for

high

speed,

precision,

and

strong

rigidity

-

Precision

self-centering

chuck

(standard

three-jaw

manual

chuck)

-

Electric

four-station

tool

post

with

precision

gear

plate

positioning

-

Tailstock

with

fast

cam

clamping

device

and

drill

bit

rotation

prevention

Technical

Parameters

|

Model

|

CK6140A

|

|

Max.

Swing

Dia.

Over

Bed

|

Φ400mm

|

|

Max.

Swing

Dia.

Over

Cross

Slide

|

Φ225mm

|

|

Processing

Length

|

750mm/1000mm

|

|

X/Z

Axis

Fast

Feeding

Speed

|

6/8

M/MIN

|

|

X/Z-axis

Repeatability

|

0.012/0.013mm

|

|

Clamping

|

3

Jaw

Manual

Chuck

(optional

pneumatic

or

hydraulic

chuck)

|

|

Tailstock

Sleeve

Travel

|

120mm

|

|

Tailstock

Taper

|

MT4

|

|

Dimension

|

2120/2370×1400×1700mm

|

|

Weight

|

1800/1950kg

|

|

Power

Supply

|

380V

3

phase

(customizable

for

local

requirements)

|

Customization

Options

We

offer

various

customization

services

to

enhance

your

CNC

lathe's

capabilities:

-

Bar

feeder

integration

for

improved

efficiency

and

productivity

-

Small

CNC

lathe

configuration

for

workshops

and

small-scale

manufacturing

-

Horizontal

lathe

conversion

for

turning

long

and

large

diameter

workpieces

Support

&

Services

-

24-hour

online

support

via

email,

phone,

WeChat,

WhatsApp,

Skype

-

Immediate

problem

analysis

and

professional

solutions

-

1-year

warranty

for

the

whole

machine

with

free

replacement

parts

-

Lifetime

free

technical

support

-

Overseas

service

with

engineer

support

for

debugging,

installation,

and

maintenance